Innovative technologies and control strategies for energy-efficient improvement, sustainability, and flexible cooling in a next-generation refrigerator

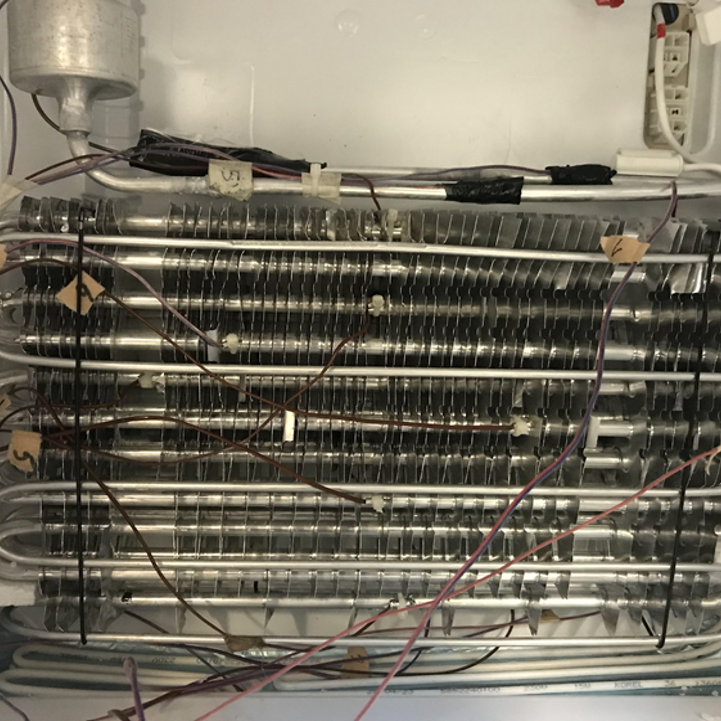

Experimental setup of defrost optimisation studies.

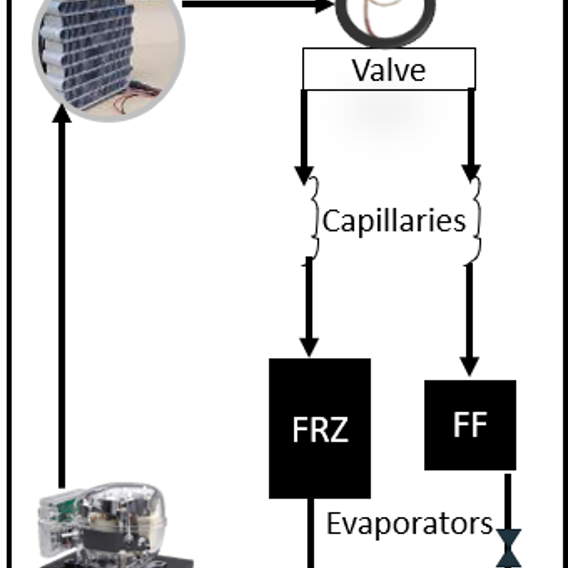

Full-Parallel Cooling System Design.

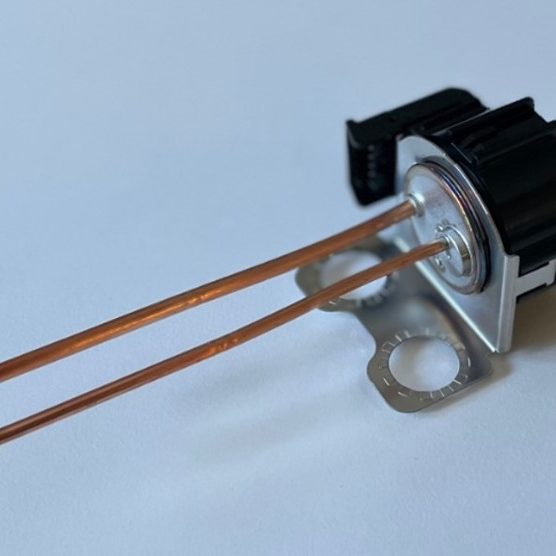

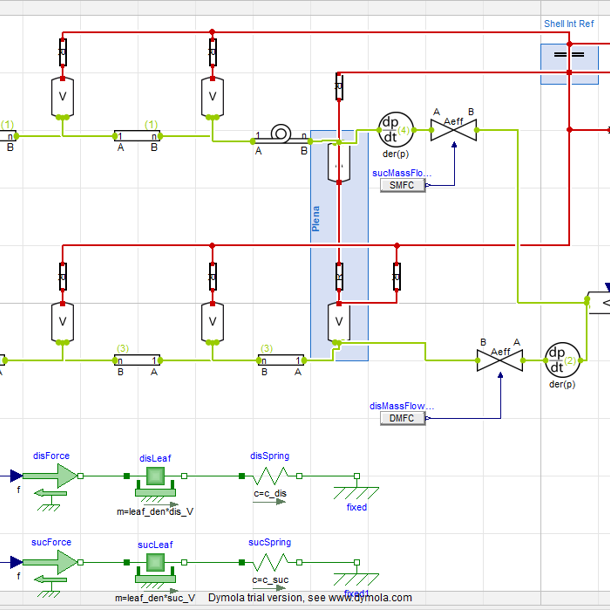

Modelling the EEV component on the cooling cycle.

Next generation refrigerator

Location:

Arçelik, Istanbul, Turkey

Application:

Household appliance

Impact:

Reduction of GHG emissions and energy consumption

Description of the DEMO: To reach a high level of sustainability and resilient cooling goals, EEV application, full parallel system design, and defrost optimisation are promising technologies.

| Results

It has been established that the energy consumption of the refrigeration system with the electronic valve could reduce by about 2 %. These outcomes are significant in the design of high-energy-efficiency class refrigerators fitting the new version of the energy consumption regulations. Experiments were conducted to assess the possibility of using an isobutane-propane mixture (R600a/R290) as a drop-in substitute to isobutane (R600a) in a particular domestic freezer. Although the decrease percentage of run-time ratio was between 10.9% and 31.1% case-specific, the corresponding increments in compressor power were between 17.0% and 76.3%. Thus, it has been concluded that further studies should be carried out on enhancing the mechanical losses, isentropic losses, and systematic design variables. At the mass percentage of 90-10% (R600a- R290) the energy consumption was decreased by 2.5%. In addition to these issues, in order to reduce the total heat gain and increase the cycle efficiency, 4% heat gain improvement can be achieved according to alternative effective PU and VIP insulation studies. Publications: 1) “Performance evaluation of a domestic freezer with R600a and zeotropic mixtures of R600a/R290”, 15th IIR- Gustav Lorentzen Conference on Natural Refrigerants (GL2022). Proceedings. Trondheim, Norway, June 2022. 2) “Energy Consumption Performance Evaluation of a Household Refrigerator with Electronic Expansion Valve”, The 26th International Congress of Refrigeration (ICR2023). Proceedings. Paris, France, August 2023. 3) “The Effect of Capillary Tube Parameters and Use of Multi-Capillary on Energy Consumption in Vapor Compression Cycle”, Cukurova 9th International Scientific Researches Conference. Adana, Turkey, October 2022 |

MAIN CONTACT:

Serdar Kocatürk : serdar.kocaturk@arcelik.com

Mutlu İpek : mutlu.ipek@arcelik.com

Gökmen Peker : gokmen.peker@arcelik.com

Cem Berk Tuzcu, cemberk.tuzcu@arcelik.com

Hüseyin Cura, huseyin.cura@arcelik.com