The ammonia-water absorption-compression heat pump (ACHP) demonstrator with an auxiliary system providing industrial-relevant boundary conditions in NTNU.

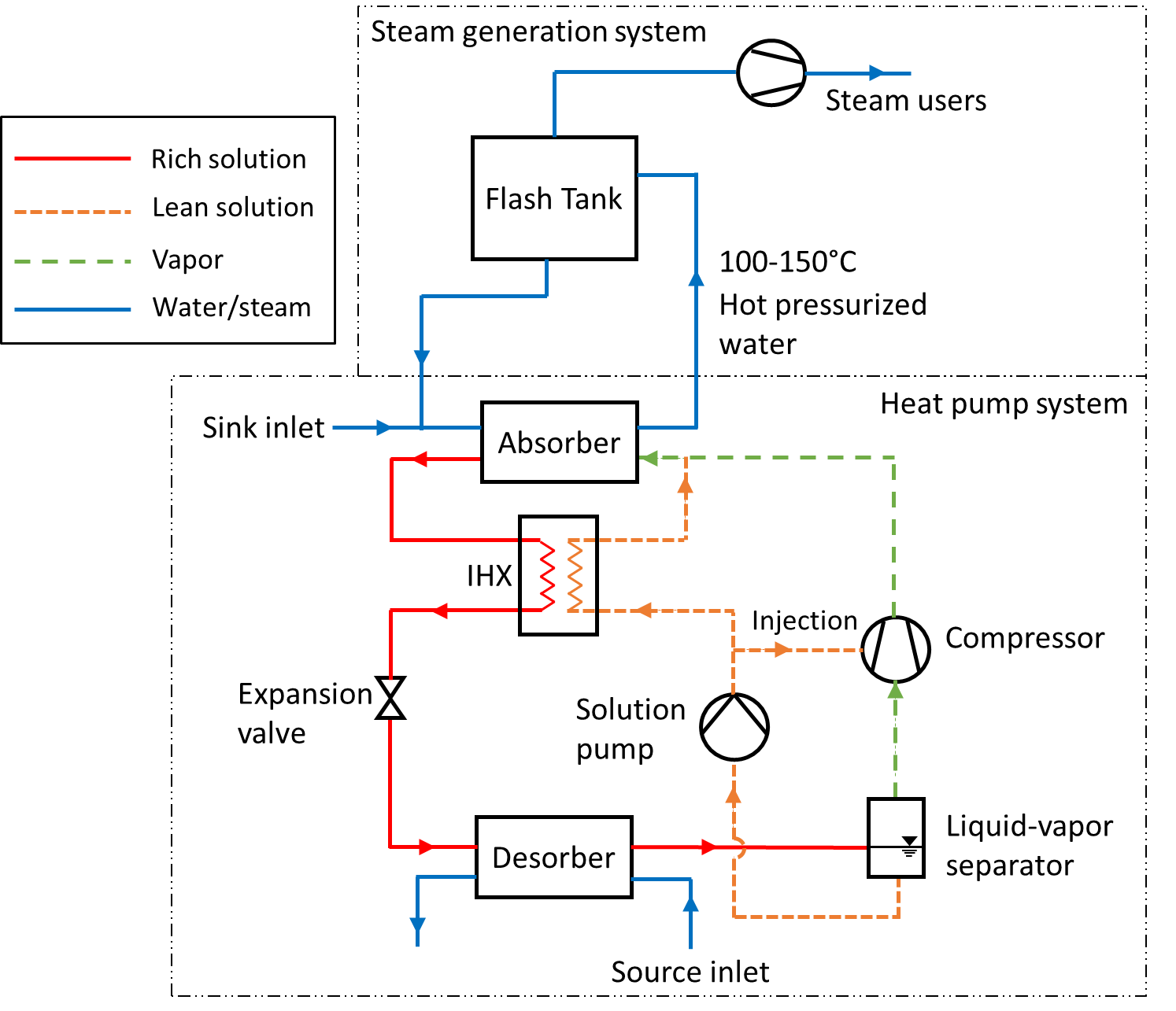

A principle sketch of the ACHP system for steam generation.

150°C steam production heat pump

Location:

NTNU (Norwegian University of Science and Technology), Trondheim, Norway

Food Category:

Meat

Application:

Steam Production

Main Chain Link:

Process

Impact:

GHG emissions reduction; waste heat recovery; energy consumption reduction

The ammonia-water absorption-compression heat pump (ACHP) cycle combines the technologies of an absorption and vapour compression heat pump with a mixture of ammonia and water as the natural working fluid.

Heat is extracted and released at non-constant temperature glides and the necessary compression ratio is lower compared to conventional vapour compression heat pumps.

The ACHP can combine both cooling and heating processes and achieve high heat sink temperature up to 150°C, which is suitable for replacement of fossil fuel boilers. These properties make the ACHP a promising system for high-temperature applications in the food supply chain, such as meat processing, fish processing, and dairies.

The ACHP demonstrator in NTNU can provide industrial-relevant boundary conditions and the flexibility to optimize the operating parameters, conditions and components for the ACHP applications in different food processes.

It serves as a starting point for further research by combining theoretical approaches, possible solutions, and experimental results.

MAIN CONTACTS:

Armin Hafner, armin.hafner@ntnu.no

Shuai Ren, shuai.ren@ntnu.no