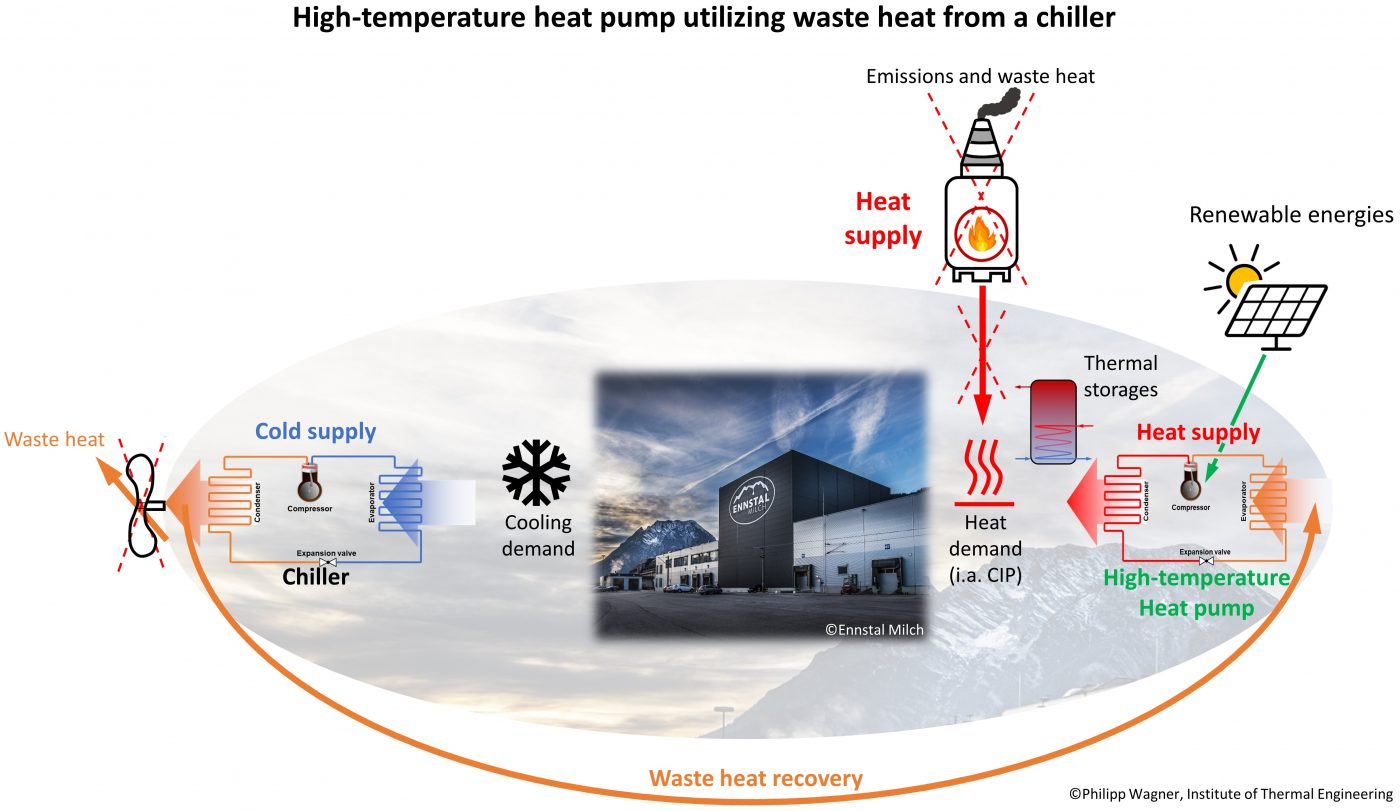

Schematic integration of the high temperature heat pump

Main components of the installed high temperature heat pump at the dairy

Exemplary day of operation: the course of the temperatures, volume flow rates as well as the electrical power consumption, refrigeration and heating capacity of an exemplary day of operation.

HTHP Dairy Austria

Location:

Ennstal Milch KG, Bahnhofstraße 182, 8950 Stainach

Food Category:

Dairy

Application:

High temperature heat pump

Main Chain Link:

Process

Impact:

Reduction of the greenhouse gas emissions by reducing the demand of steam for a cleaning-in-place system with a high temperature heat pump by utilizing waste heat from a chiller. Currently ca. 200 tCO2 savings per year (compared to a heat supply with natural gas) can be achieved. Further potential can be exploited if additional consumers will be supplied by the high temperature heat pump

The Austrian dairy Ennstal Milch covers all process steps from fresh milk to final products (e.g. whole milk, desserts, spreads, moulded cheese, …) including farm milk collection. One of the currently operating chillers with a refrigeration capacity of ca. 900 kW supplies the ice water cooling system of the production with water at around 1 °C. The chiller uses the environmentally-friendly refrigerant ammonia. Originally the chiller has dissipated ca. 1100 kW of heat unused to the environment.

Besides the cooling demand there is also a significant heat demand for the production processes of the dairy (warm water, cleaning-in-place (CIP) system), which is traditionally covered by steam. By integrating a high temperature heat pump (HTHP) into a chiller, waste heat can be upgraded to a temperature level of ca. 90 °C, which can be used to partially replace the steam demand.

For this demonstrator an ammonia HTHP with a heating capacity of 500 kW was directly integrated into an existing chiller. On the one hand with this promising technology waste heat can be utilized and on the other hand, the steam demand for process heat can be significantly reduced. Recently the HTHP started its operation and a monitoring is taking place. Actually, simulations models are set up for the optimization of the operation as well as for the evaluation of the integration of further hot-water consumers to exploit the full potential of the HTHP.

MAIN CONTACTS:

Thomas Demmerer (thomas.demmerer@equans.com), ENGIE Kältetechnik

René Rieberer (rene.rieberer@tugraz.at), Graz University of Technology, Institute of Thermal Engineering