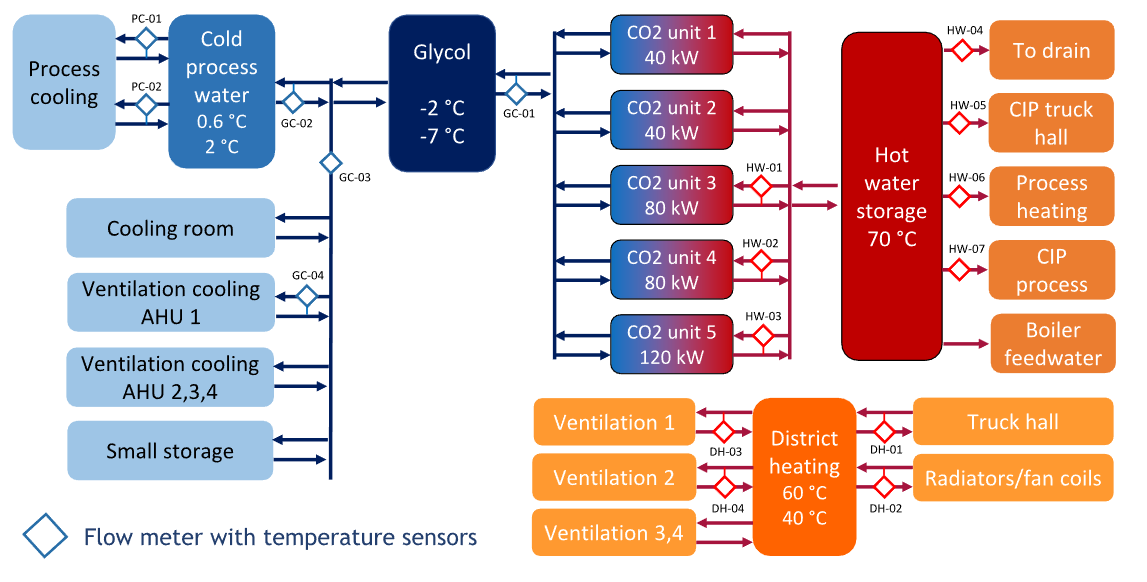

Simplified overview of the thermal energy system and the installed fow sensors at the dairy plant.

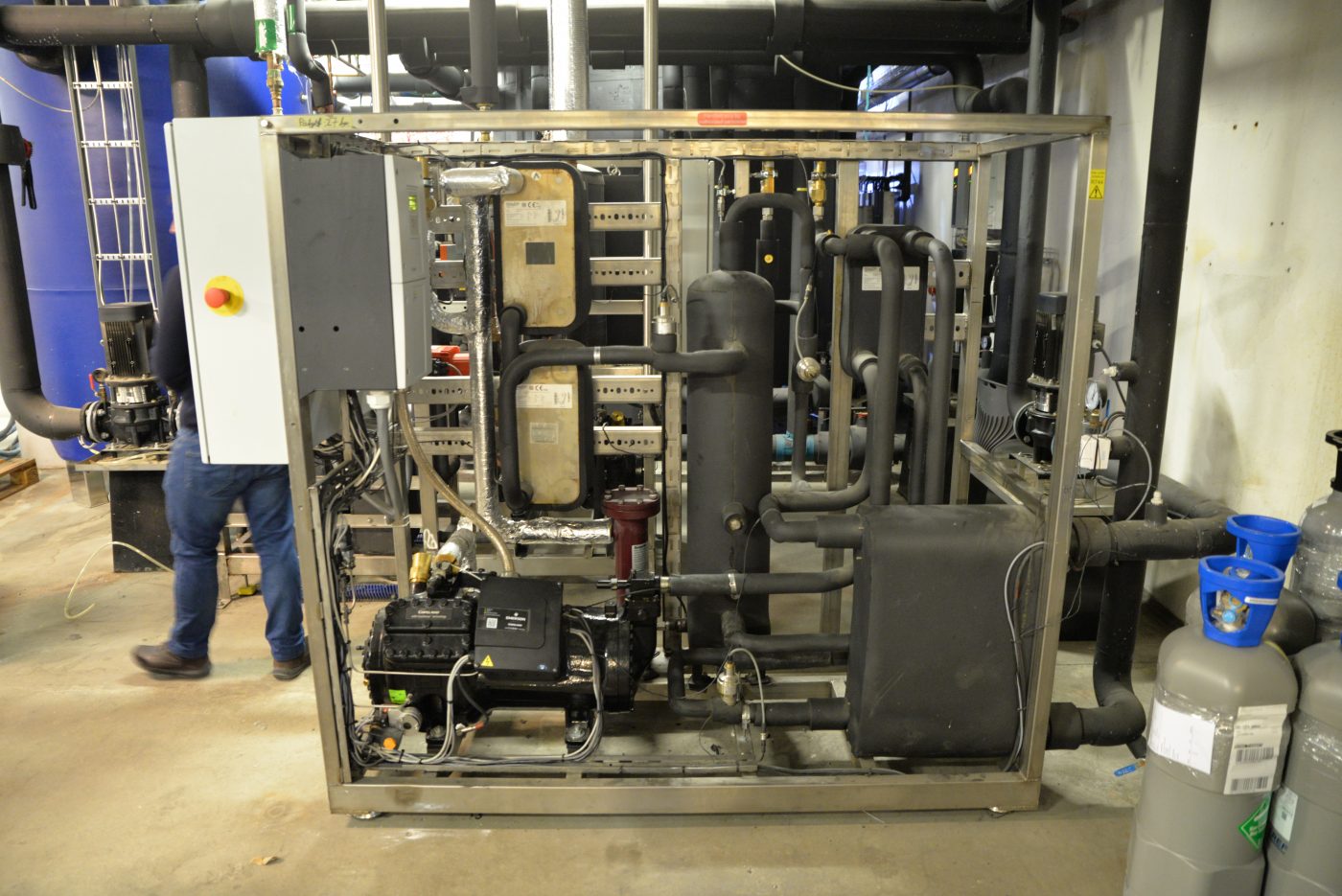

The CO2 refrigeration unit in Rørosmeieriet AS.

Installed Energy flow meter including a mass flow meter and two temperature sensors.

Energy smart dairy

Location:

Rørosmeieriet AS, Røros, Norway

Food Category:

Dairy

Application:

Dairy energy system

Main Chain Link:

Process

Impact:

Energy efficiency improvement; GHG emissions reduction; waste heat recovery.

Rørosmeieriet AS (RM), founded in 2001, is the largest organic dairy in Norway. A CO2 refrigeration system is the core of the current thermal energy system. It consists of five parallel units, connecting the cold and warm sides of the process.

On the cold side, cold glycol is circulated and utilized for cooling process water, cooling air in the cold storage room, and air conditioning. On the warm side, the CO2 refrigeration units produce hot water for process heating, cleaning in place (CIP) as well as domestic hot water. The excess hot water is stored in a hot water tank system.

In this demonstrator, detailed mapping of the current energy flows in RM will be conducted to identify the thermal demands and requirements. The energy system will be optimized, and process integration strategies will be proposed for the energy efficiency improvement and GHG emissions reduction.

These optimizations aim to reduce the specific energy consumption per liter of milk by around 36% to 0.09 kWh/l, while at the same time saving water. The potential for installing a cold thermal energy storage system will the evaluated to increase the flexibility and robustness of the refrigeration system.

MAIN CONTACT:

Jan Bengsch, jan.bengsch@sintef.no