The Austrian dairy Ennstal Milch covers all process steps from fresh milk to final products, including farm milk collection. Dairies have an energy intensive demand for refrigeration but also significant heating demand for the production processes of the dairy (e.g. cleaning-in-place (CIP) system and hot water), which is traditionally covered by steam.

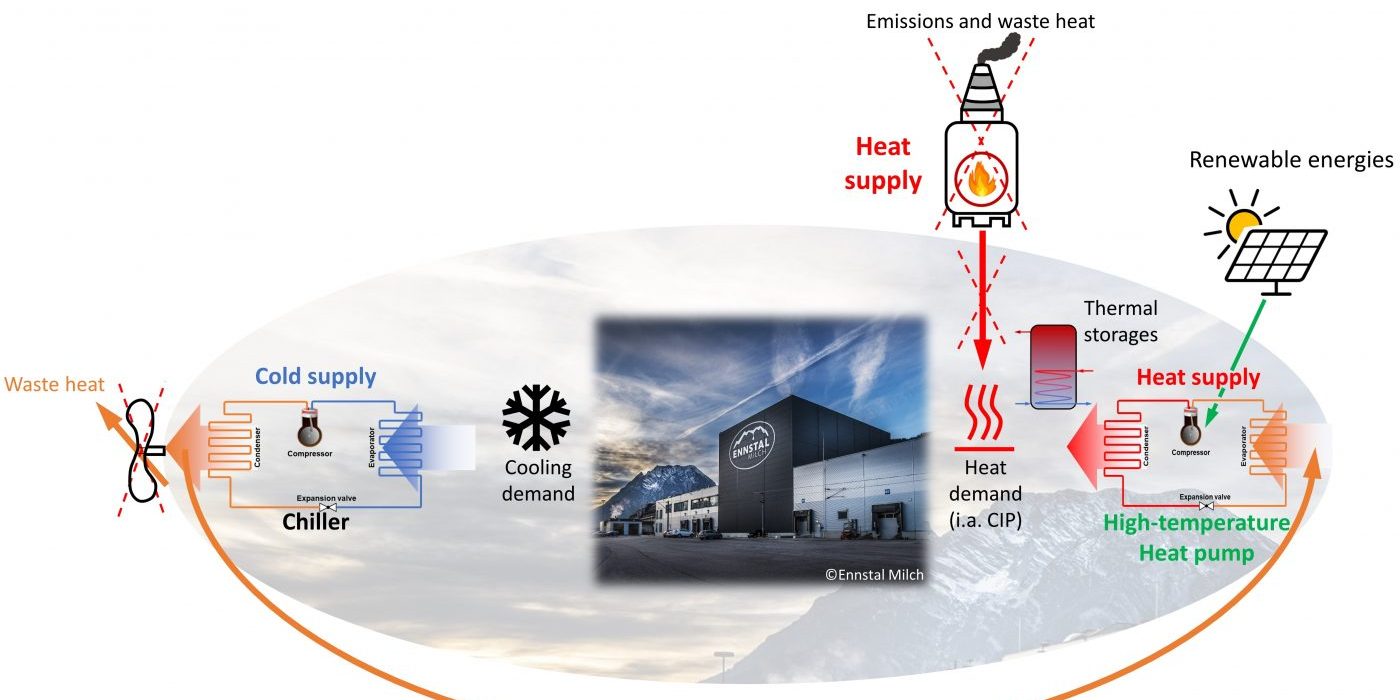

In this ENOUGH demonstrator (read more here) an ammonia HTHP with a heating capacity of 500 kW was directly integrated into an existing chiller, enabling the utilization of the waste heat to significantly reduce the steam demand for process heat (see figure). The direct integration into the refrigerant cycle enables a very efficient operation since no heat exchangers are needed between the chiller and the HTHP, which would increase the necessary temperature lift in each stage. The HTHP already started its operation and monitoring is taking place. Simulation models are set up for the optimization of the operation as well as for the evaluation of the integration of further hot-water consumers to exploit the full potential of the HTHP.

The installed system and an example of daily operations in the Austrian dairy demonstrator.

The system is used in a dairy during ongoing production and supplies heat to a CIP system by recovering waste heat from a chiller. In terms of reducing greenhouse gas emissions in the food industry, this concept can make a significant contribution. It offers the possibility of generating process heat by utilising waste heat (from a chiller) by means of a heat pump using an environmentally friendly refrigerant (R717) and CO2-free electricity instead of burning natural gas.

Interim results include:

- Heat supplied by the HTHP (ca. 2.7-3 MWh / day)

- GHG-savings compared to natural gas (ca. 600 kgCO2/day = ca. 200 tCO2/a)

Further work until the end of the project will cover model-based investigations with respect to possible improvements in the operation of the HTHP. To investigate the heating demand of the CIP-system, a simulation model including the vessels to be cleaned will be completed. With the aim of the simulation model, changes to the operation (e.g. different target temperatures in the storage tanks of lye and acid, a different routing of the fluids including the storage tanks or different set-points for the operation of the HTHP) will be simulated and the consequences for the operation of the HTHP will be evaluated. Additionally, the supply of further process equipment (which now uses steam) with hot water from the HTHP will be investigated and realised if feasible.