Plate freezer test facility.

CO2 -50°C plate freezer

Location:

NTNU, Trondheim, Norway

Application:

Fish & meat freezing

Impact:

GHG emissions reduction; energy consumption reduction; increase of shelf life; food loss reduction; food quality improvement.

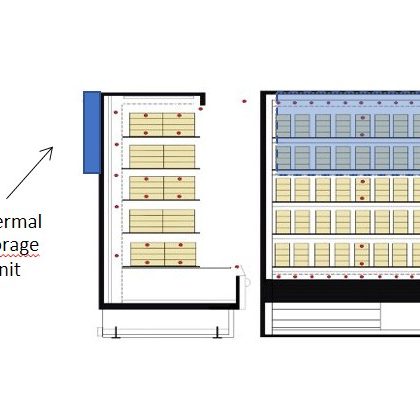

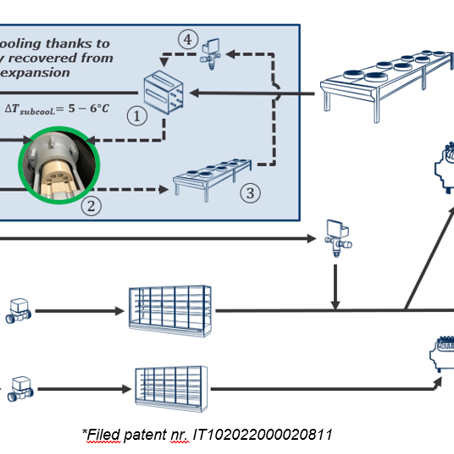

| Efficient cooling and freezing systems using natural refrigerants are a sustainable solution for food loss and waste reduction in the food supply chain, especially for the prevention of the loss of raw materials. NTNU implements a real size industrial plate freezer (Plates: 2×3 m) into a dedicated CO2 refrigeration system into the laboratory infrastructure. Due to CO2 liquid circulation, the unit can provide more than 100 kW of cooling capacity at evaporation temperatures between -30 and -50°C.

A scientific approach will be applied to understand how to optimize the freezing time, product/package thickness in relation to energy demand and shelf life. The goal is to disseminate operation instructions and recommendations to minimize the carbon footprint of dedicated products within the fish and meat sector. The freezer can be widely used within the food processing industry at various freezing temperature levels. MAIN CONTACT: Armin Hafner, armin.hafner@ntnu.no Shuai Ren, shuai.ren@ntnu.no

|