Prototype of a refrigerated truck for short delivery. The refrigeration unit is powered by an electric motor. The photovoltaic panels reduce the consumption of primary energy and extend the refrigeration unit autonomy.

Prototype of a natural refrigerant CO2 system under test at the Construction Technology Institute – National Research Council (Italy).

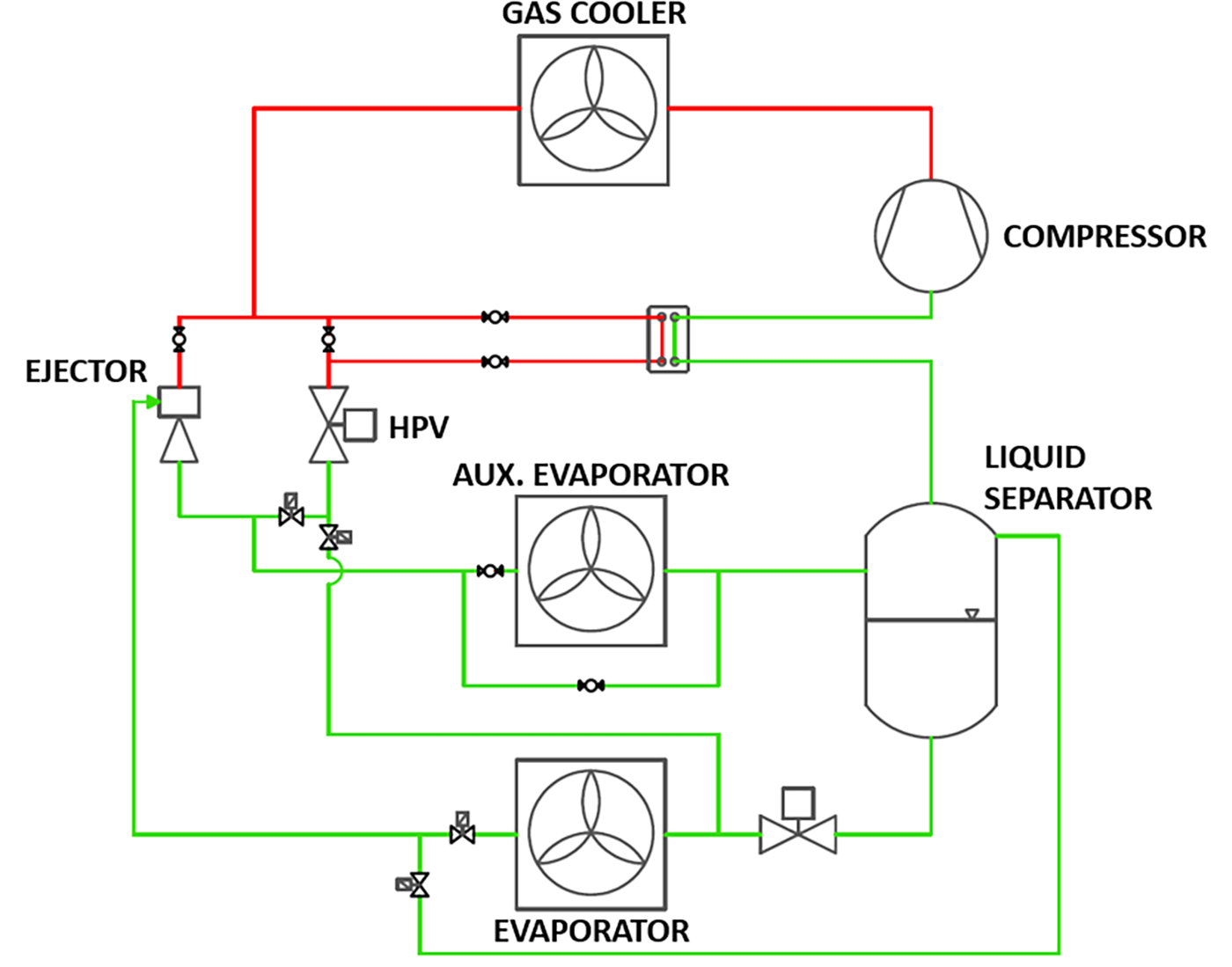

Schematic of the CO2 refrigeration unit using a two-phase ejector to recover the expansion work and an auxiliary evaporator to enhance the cycle performance.

Fresh and Green Delivery

Location:

Northern Italy

Food Category:

Meat, Fish, Fruits & Vegetables, Dairy

Application:

Transport

Main Chain Link:

Transport

Impact:

GHG emissions reduction: 6.000 tonnes of CO2 equivalent per year, from motor fossil fuel and direct HFC refrigerant emission.

Transport is one of the most critical links of the supply chain, occurring at many stages.

The relevance of short distance transport and home delivery has been increasing during the last months due to the COVID pandemic and home delivery has spread in areas where traditional shopping was still the predominating way.

Nevertheless, this sector has to face many key problems such as pollution and noise emission in city centres and the effects caused by refrigerant leakage.

The “Fresh and Green Delivery” demonstrator will integrate natural refrigerants and take advantage from solar energy to minimise GHGs emissions. On one side, the use of a natural refrigerant will prevent the emissions related to the lifecycle of synthetic refrigerants. The CO2 refrigeration unit will include advanced solutions to increase the overall performance of the system, lowering the energy request to preserve the transported food. On the other side, the integration of rooftop photovoltaic panels will further reduce the draw of primary energy of the system thanks to the produced electricity during the day.

An integration of this system with hybrid or plug-in electric trucks will further decrease the environmental impact in term of localized emissions and noise.

MAIN CONTACT

Antonio Rossetti:antonio.rossetti@itc.cnr.it