Brine freezing of mackerel may reduce the time for freezing in the air tunnel by 50%

Brine freezing of fish.

Location:

Ålesund, Norway

Food Application:

Fish

Application:

Fish processing industry

Main Chain Link:

Process

Impact:

Reduction of specific energy consumption (SEC) related to the freezing process of fish. For two-stage freezing of mackerel: 10-20% reduction in energy consumption and 50% time-reduction for tunnel freezers.

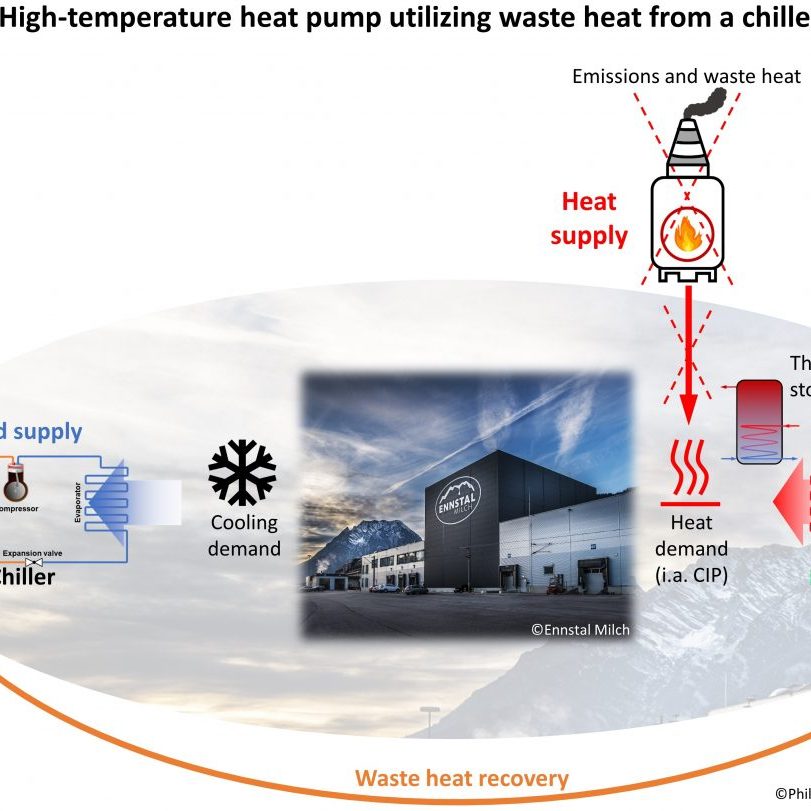

Freezing of seafood products are usually carried out by either air blasting, plate freezing or immersion freezing (e.g., brine freezing). There is no “one-size-fits-all” solution, and the choice usually come down to a balance between freezing time (production rate), energy costs and investments costs. The motivation to look into brine freezing is the great heat transfer properties it can provide. When immersing a food product in brine, you usually get good contact with the entire food surface, and agitated liquids provides high heat transfer coefficients. In essence, brine freezing is very energy efficient, and previous theoretical studies show that the SEC of brine freezing is almost half of that of tunnel freezing (0.08 vs 0.15 kWh/kg whitefish).

This demonstrator will explore various applications for brine freezing in the seafood industry. One of the potential applications is two-stage freezing of mackerel. Today, freezing of pelagic fish is done in air blast freezing tunnels where the fish is packed in 20 kg cardboard boxes and put on racks. Huge amounts of fish are batch-frozen, typically 100-300 tonnes, in a process lasting 20-22 hours. Large fans are circulating the air in the tunnel, and the heat transfer is decreasing towards the end of the freezing period. By partly freezing the mackerel in a brine freezer before entering the tunnels, the goal is to reduce the freezing time in the tunnel to 11 hours. The capacity of the plant may therefore be doubled compared with todays production. Furthermore, brine freezing is about 50% more energy efficient than air tunnels, and the tunnels themselves get more energy efficient when holding times in these are reduced. For this case, it is expected to reduce the total energy consumption by 10-20% and even higher if the process is optimised.

Brine freezing of salmon is another potential application. The standard today is to single freeze gutted salmon in air tunnels, so there is a potential to unlock the same energy demand reduction as for the mackerel case. However, due to quality changes such as decolourisation and salt uptake, the freezing process must be customised for this purpose to maintain the same level (or improved) of quality as today.

MAIN CONTACT:

Eirik Starheim Svendsen (eirik.starheim.svendsen@sintef.no)