Blast freezer at Enex’s workshop

Blast freezer

Location:

Treviso, Italy

Food category:

Meat, Fish, Fruits & Vegetables, Dairy

Application:

Processing (main product:Fish)

Main Chain Link:

Retail

Impact:

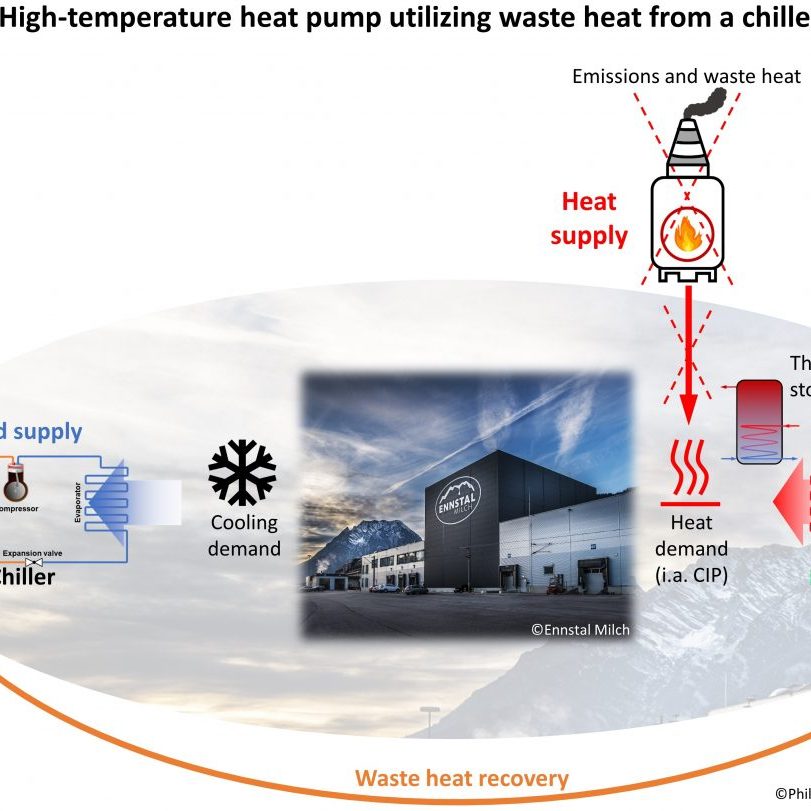

Use of natural refrigerants, reduction in energy consumption (target 15-20%) in food processing, Improved freezing process for better food quality

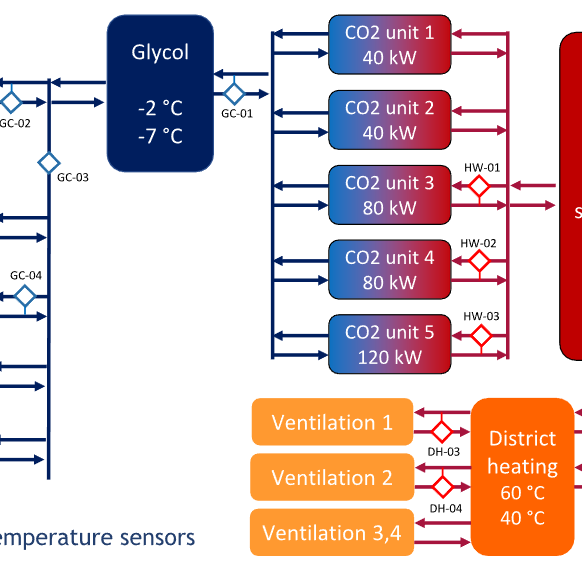

The demo consists in an ultra low temperature CO2 direct expansion unit for food blast freezing, to be used in freezing tunnels, conveyors, spirals, etc.

Fast freezing is assured by extremely low evaporation temperature (close to -50°C) and high air volume flow.

State-of-the-art technologies are applied for optimal use of heat transfer surface, suitable compressor and lubricant, defrosting and unit control.

Possibility of improving performance by two-phase ejector is evaluated according to specific application.

The technology is suitable for Hot climate (South Europe).

Heat recovery and Thermal Energy Storage can be included for smart integration of heating (DHW, CIP) and cooling in food processing plants.

Integration with renewables (geothermal or PV) is easily applicable.

MAIN CONTACT:

Sergio Girotto, ENEX S.r.l. sergio.girotto@enex.it